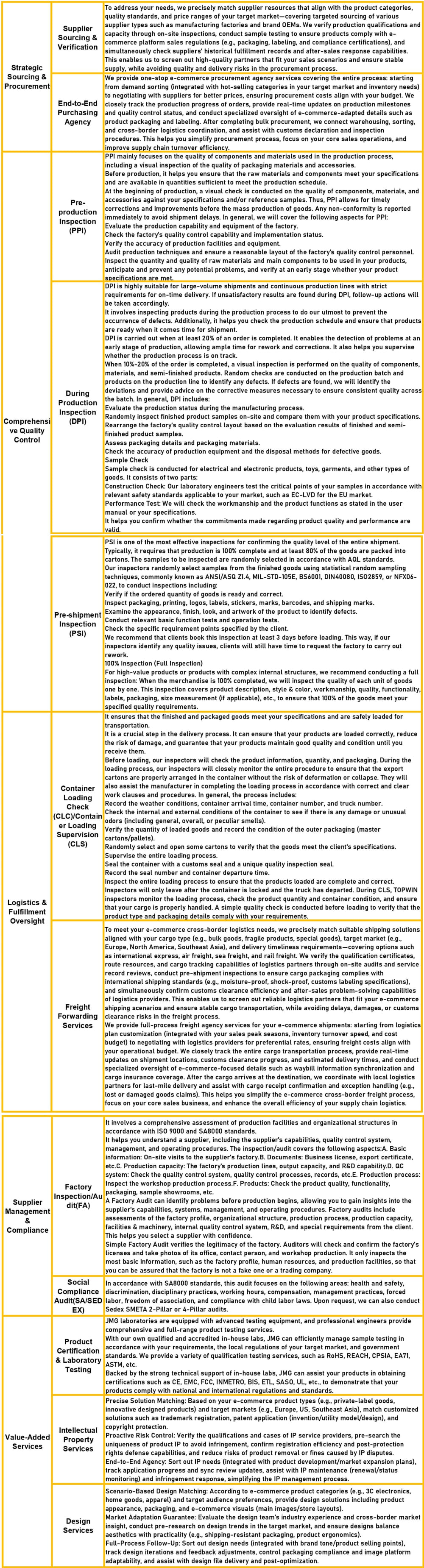

It involves a comprehensive assessment of production facilities and organizational structures in accordance with ISO 9000 and SA8000 standards.

It helps you understand a supplier, including the supplier's capabilities, quality control system, management, and operating procedures. The inspection/audit covers the following aspects:A. Basic information: On-site visits to the supplier's factory.B. Documents: Business license, export certificate, etc.C. Production capacity: The factory's production lines, output capacity, and R&D capability.D. QC system: Check the quality control system, quality control processes, records, etc.E. Production process: Inspect the workshop production process.F. Products: Check the product quality, functionality, packaging, sample showrooms, etc.

A Factory Audit can identify problems before production begins, allowing you to gain insights into the supplier's capabilities, systems, management, and operating procedures. Factory audits include assessments of the factory profile, organizational structure, production process, production capacity, facilities & machinery, internal quality control system, R&D, and special requirements from the client. This helps you select a supplier with confidence.

Simple Factory Audit verifies the legitimacy of the factory. Auditors will check and confirm the factory's licenses and take photos of its office, contact person, and workshop production. It only inspects the most basic information, such as the factory profile, human resources, and production facilities, so that you can be assured that the factory is not a fake one or a trading company.